Description:

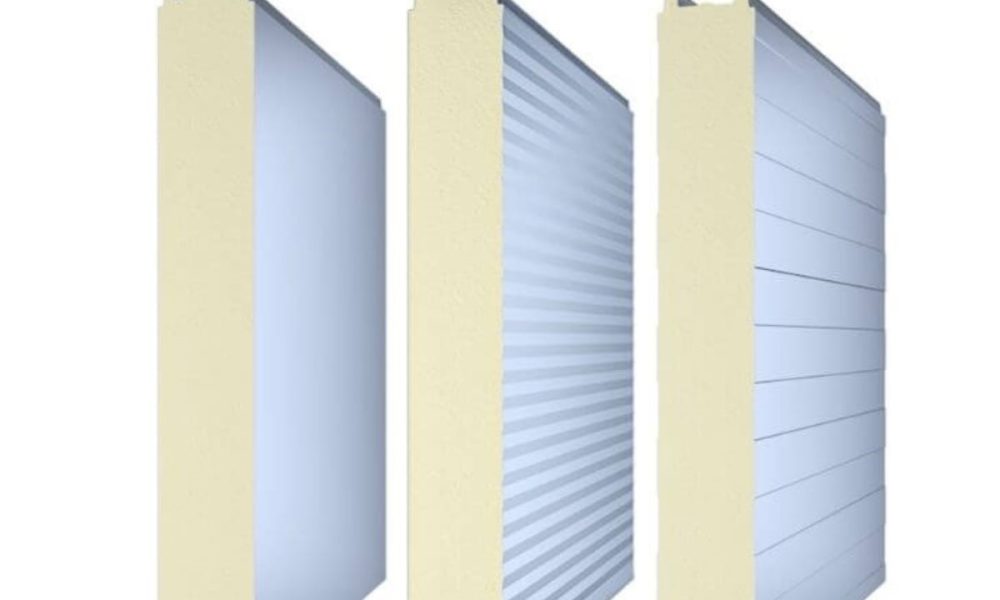

PUR (Polyurethane) Wall Panels are insulated panels designed for high-performance thermal insulation and energy efficiency in wall applications. These panels consist of a rigid polyurethane foam core sandwiched between two layers of pre-painted or galvanized steel. PUR Wall Panels provide superior insulation, making them ideal for applications that require temperature control, such as cold storage, clean rooms, and industrial buildings. They are lightweight, durable, and offer excellent fire and moisture resistance.

Specifications:

| Item | Details |

|---|---|

| Material | Pre-Painted Galvanized Steel (PPGI) / Aluminum |

| Coating | Zinc Coating / Polyester / PVDF Coated |

| Core | Rigid Polyurethane Foam (PUR) |

| Thickness | 40 mm to 200 mm (Core thickness) |

| Profile | Flat or Micro-Ribbed Panel Profile |

| Length | Customizable (Up to 12 meters) |

| Width | Standard: 1,000 mm |

| Standards | ASTM C518, EN 14509, IS 14246 |

Raw Materials:

The PUR Wall Panels are manufactured using high-quality galvanized or aluminum steel sheets, bonded to a rigid polyurethane foam core. The foam core provides excellent thermal insulation while the steel or aluminum layers offer structural strength and resistance to external elements.

RAL Colors Available:

PUR Wall Panels come in various RAL colors to match project aesthetics and functional needs. Popular RAL colors include:

Custom colors and finishes are available on request.

Features:

Applications:

PUR Wall Panels are widely used in applications requiring high insulation and temperature control. Typical applications include:

Leading provider of sandwich panels, wall panels, tubes, L-beams, and pipes in the UAE, ensuring quality and reliability.